Series and prototype 3D PRINTING

HP Multi Jet Fusion 5200

More about MJF

3D Print of Voluminous Parts

Stratasys F900

More about FDM

Postprocessing Surface Finishing

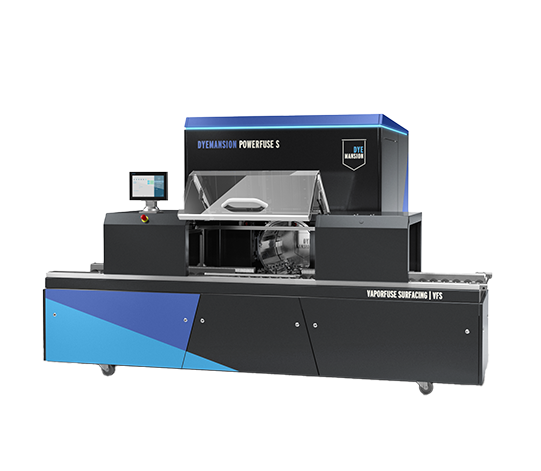

DyeMansion Powerfuse S More about finishing

Postprocessing Spray Painting

3D scanner GOM ATOS Q

an accurate, fast, versatile, and reliable scanner More about scanning

Rapid Prototyping

Mass Production of End Parts

Engineering and Optimization

Multi Jet Fusion HP Jet Fusion 5200

revolutionary, fast, precise, and environmentally friendly technology

Technology

Multi Jet Fusion is a technology that uses powder for production, without the use of lasers.

By using a plotter, the bonding agent is sprayed onto the areas where we want to turn the powder into a part.

Subsequently, a highly efficient infrared lamp cures the areas where the agent has been applied.

The print area is moved one layer lower and the entire process is repeated.

The finished parts are removed from the construction chamber with a vacuum after the powder has cooled down.

We can reuse the vacuumed unbaked powder.

data sheet HP JF 5200

Materials

We use only material from Hewlett Packard: Polyamid PA 12

data sheet PA 12

Application and advantages of FMJ technology

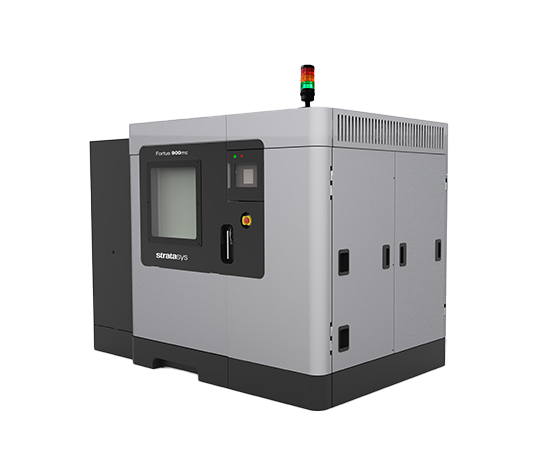

Industrial 3D Printer Stratasys F900

for 3D Printing of Voluminous Parts

Application and advantages of FDM technology

Technology

Produce highly precise 3D printed parts with repeatability and reliable performance on the best FDM industrial 3D printer on the market.

Popular in aerospace, automotive, and industrial manufacturing.

Print chamber dimension 914.4 × 609.6 × 914.4 mm.

Materials:

Filaments certified for various industries.

Standard thermoplastics support general 3D printing applications and include versions of ABS compliant with ESD and biocompatibility. Technical and high-performance materials, including nylon, carbon fiber, PEI, and PEKK, provide the right properties for demanding applications. ULTEM™ is a registered trademark of SABIC and affiliated companies.

Explore more than 25 materials to handle applications across virtually any industry.

Product Sheet Stratasys F900 (PDF)

Technical Specifications Stratasys F900 (PDF)

Materials

Antero™ 800NA (polyether

ketoneketone)

High thermal and chemical resistance. Low volatility and high dimensional stability. Excellent strength, stiffness, and wear resistance.

Spec sheet for Antero™ 800NA (EN, PDF)

Antero 840CN03 (polyether

ketoneketone)

Excellent ESD (electrostatic) properties, strength, stiffness, and abrasion resistance. High thermal and chemical resistance. Low volatility and high dimensional stability.

Spec sheet for Antero 840CN03 (EN, PDF)

PPSF (polyphenylsulfone)

Mechanically excellent material, highest strength. Ideal for use in corrosive and highly thermally demanding conditions.

Spec sheet for PPSF (EN, PDF)

ULTEM™ 1010 resin (polyetherimide)

Highest thermal resistance, chemical resistance, and tensile strength. Excellent strength and thermal stability of ULTEM™ 9085 resin. High thermal and chemical resistance; highest flexural strength. Meets FST (flame, smoke, toxicity) requirements. Additional colors beyond standard natural and black are available as validated materials by Stratasys.

Spec sheet for ULTEM™ 1010 resin (EN, PDF)

ULTEM™ 9085 resin (polyetherimide)

High thermal and chemical resistance; highest flexural strength. Meets FST (flame, smoke, toxicity) requirements. Additional colors beyond standard natural and black are available as validated materials by Stratasys.

Spec sheet for ULTEM™ 9085 resin (EN, PDF)

ST-130™

Specially designed for hollow composite parts. Fast dissolution without manual processing. High resistance to heat and pressure in an autoclave.

Spec sheet for ST-130™ (EN, PDF)

FDM® Nylon 12CF

Carbon fiber-reinforced thermoplastic with excellent structural properties. Highest flexural strength. Highest stiffness-to-weight ratio.

Spec sheet for FDM® Nylon 12CF (EN, PDF)

FDM® Nylon 12 (polyamide 12)

The toughest nylon in additive manufacturing. Excellent for repeatedly used snap fits, pressed inserts, and fatigue-resistant applications.

Spec sheet for FDM® Nylon 12 (EN, PDF)

FDM® Nylon 6

Combines strength and toughness better than other thermoplastics. Creates durable parts with a clean surface and high resistance to breakage.

Spec sheet for FDM® Nylon 6 (EN, PDF)

PC (polycarbonate)

Precise, durable, and stable material for solid parts, metal bending tools, and working with composite materials. Excellent for demanding prototyping, tooling, and fixtures. Red and black colors are available as validated materials by Stratasys.

Spec sheet for PC (EN, PDF)

PC-ISO™ (polycarbonate - biocompatible and sterilizable)

Sterilizable with gamma radiation or ethylene oxide (EtO) sterilization. Best suited for applications requiring higher strength and sterilization.

Spec sheet for PC-ISO™ (EN, PDF)

PC-ABS (polycarbonate - acrylonitrile butadiene styrene)

Excellent mechanical properties and thermal resistance. Excellent definition of features and surface aesthetics of ABS. Red PC-ABS is available as a Stratasys-approved material.

Spec sheet for PC-ABS (EN, PDF)

ASA (acrylonitrile styrene acrylate)

For the production of UV-stable parts with the best aesthetics among all FDM materials. Ideal for outdoor infrastructure and commercial use, outdoor functional prototypes, and automotive parts and accessories prototypes.

Spec sheet for ASA (EN, PDF)

ABS-ESD7™ (acrylonitrile butadiene styrene - static dissipative)

Electrostatic dissipative material with surface resistance of 104 - 109 ohms. Great assembly tools for electronic and static-sensitive products. Widely used for functional prototypes of cases, covers, and enclosures.

Spec sheet for ABS-ESD7™ (EN, PDF)

ABS-M30™ (acrylonitrile butadiene styrene)

Versatile material suitable for form, fit, and functional applications. Well-known manufacturing material for precision prototyping.

Spec sheet for ABS-M30™ (EN, PDF)

ABS-M30i (acrylonitrile butadiene styrene - biocompatible)

Strong, biocompatible material that can be sterilized and is suitable for use in medical devices. Meets ISO 10993, USP Class VI, and ISO 18562 testing requirements.

Spec sheet for ABS-M30i (EN, PDF)

Postprocessing DyeMansion Powerfuse S

automatic device for surface finishing of the plastic parts

Application and advantages of the Powerfuse S

Technology

DyeMansion Powerfuse S is an automatic device for surface finishing of the plastic parts produced in 3D printers using the vaporization process.

During vaporization, the surface of the printed part is etched and smoothed. The parts have a significantly smooth surface with a high gloss.

• Chemical surface finishing process

• Parts are treated with aerosol, which evaporates with no waste

• Complies with standards for food contact

• Creates a smooth surface on par with injection-molded parts

• Consistent output quality

• Fast surface finishing process

Tech Sheet Powerfuse S

Design Manual Powerfuse S

Postprocessing Spray Painting

A wide selection of final paint colors according to the RAL color chart.

Technology

We apply final paint via spray painting with the professional TOPLAC paints, we specifically use the acrylic paint Glasurit.

Painted parts need to be in the range up to 150 cm, but it always depends on the particular part and its dimensions and weight.

A wide selection of final paint colors according to the RAL color chart at your disposal.

We provide controlled process for preparing parts for painting (cleaning, degreasing), as well as controlled curing process of the coating, thanks to drying programs in the paint booth.

Product Sheet Powerfuse S

-->

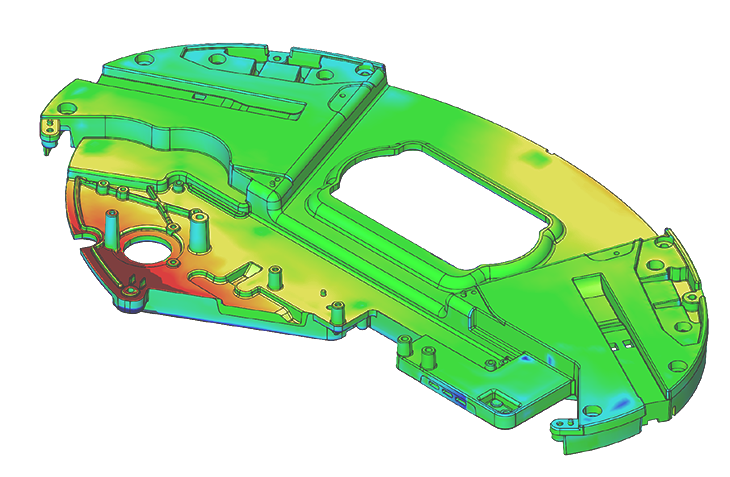

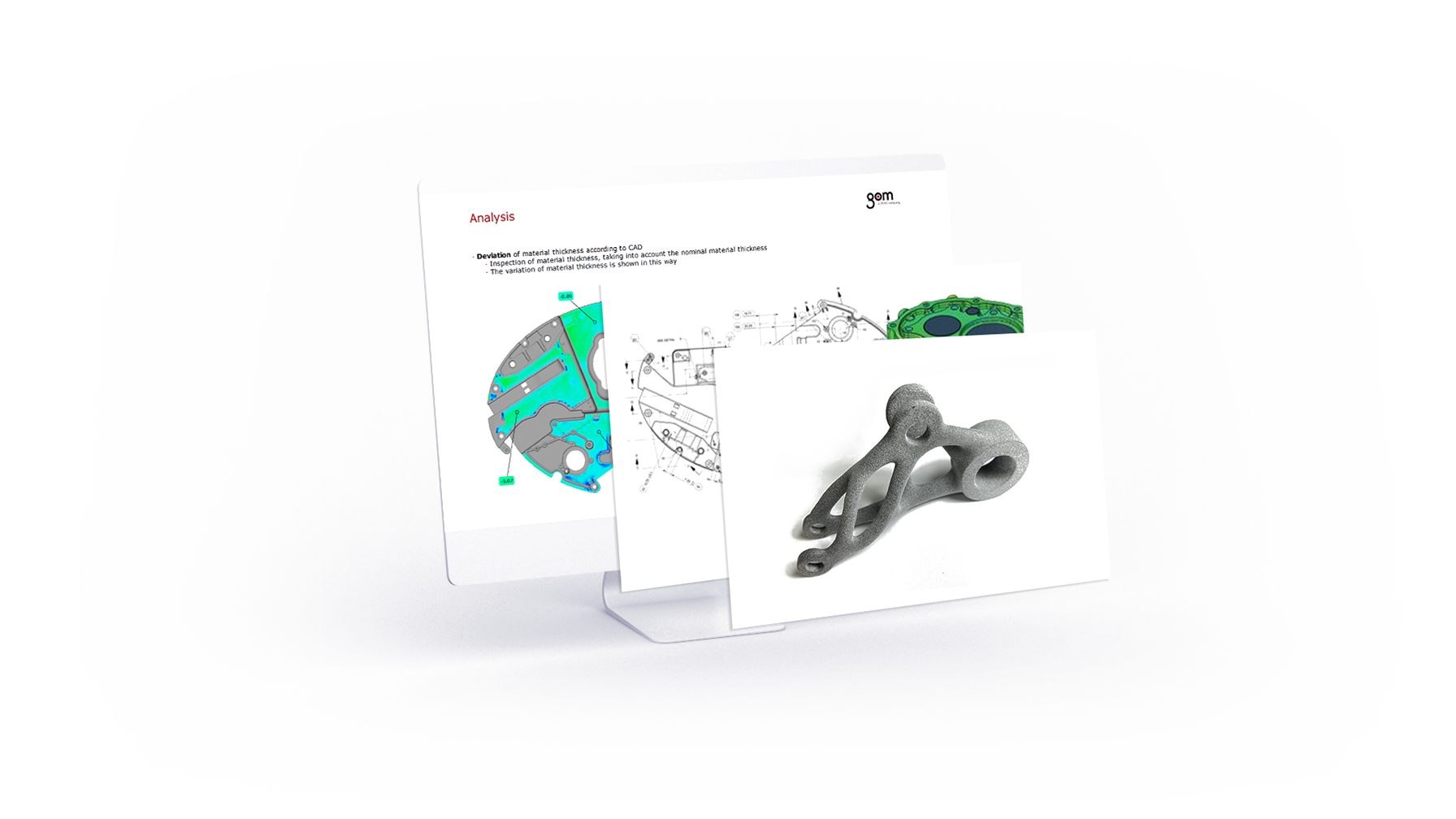

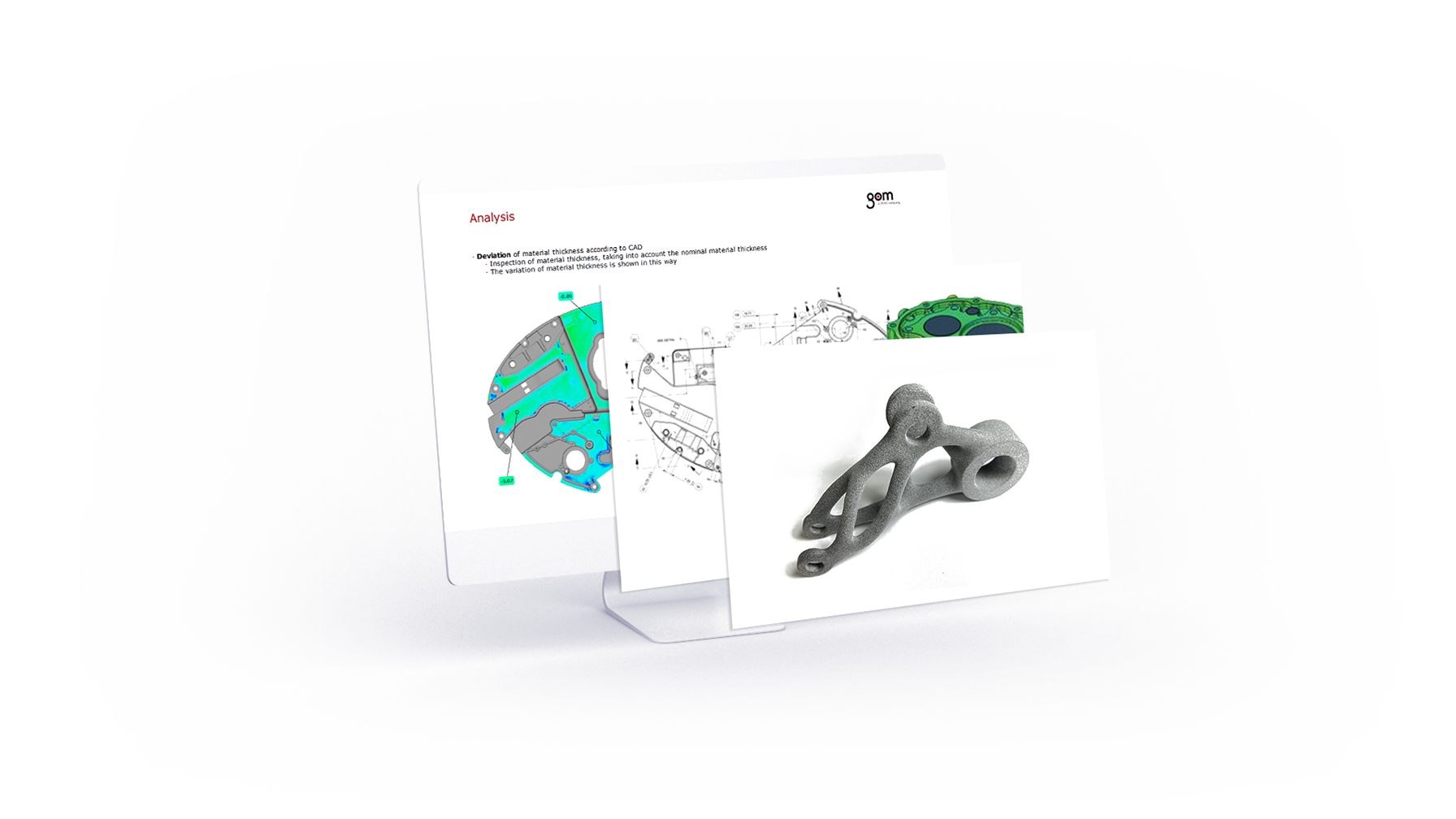

3D scanner GOM ATOS Q

an accurate, fast, versatile, and reliable scanner

Uses and advantages of the scanner

Top in scanning

We use the reliable GOM ATOS Q universal scanner, which allows scanning with horizontal and vertical blue light.

3D scanning is used for accurate and easy dimensional control and inspection of complex products or to create a 3D model of a part and then produce it on a 3D printer.

All-in-one software: inspection, evaluation, output reports.

data sheet GOM ATOS Q (EN)

Features

3D optical digitization is used to create precise copies of parts

3D optical measurement is used for dimensional verification of components against a CAD model.

Case Study

We were approached by a vintage car owner, who was enquiring about the manufacture of a new left front headlight bezel, which had been destroyed in an accident and is no longer in production.

We met the demand by scanning the right reflector and then mirroring it.

However, the right headlight was also partially damaged in the accident, so it was necessary to calculate and compensate the deformed parts during the creation of the 3D model.

Rapid Prototyping

What makes us your best option?

We specialize in rapid prototyping using advanced 3D printing technology. Our services are designed to help you quickly and efficiently transform your ideas and concepts into physical prototypes. With 3D printing, we can create prototypes of various complexities and materials with precise details and high quality.

Proč zvolit naši službu rychlé výroby prototypů?

Speed: Thanks to our modern 3D printing technology, we can create prototypes faster than traditional manufacturing methods. This means you can get your prototype in your hands much sooner.

Flexibility: 3D printing allows us to create prototypes from various materials, including plastics, metals, and even biodegradable materials. This means you have a wide range of options when developing your products.

Cost-Efficiency: With 3D printing, you can save on costs associated with traditional manufacturing processes, such as mold or tooling production.

Individual Approach: Our services are fully customizable to your needs. We are here to help you achieve your goals and visions.

Mass Production of End Parts

What makes us your best option?

We are your partner for mass-producing end parts using cutting-edge 3D printing technology. We have the experience and expertise that will allow you to efficiently manufacture end parts in large volumes while adhering to the highest quality standards.

Benefits of our cooperation:

Speed: With 3D printing, we can reduce the time required for producing end parts, enabling you to quickly respond to market demand. Your products will be in the market sooner than ever before.

Precision and Reliability: Thanks to our technologies and skills, we can achieve high precision in the production of end parts. This means fewer defects and a guarantee of product reliability.

Material Flexibility: 3D printing allows for the production of end parts from various materials, including plastics, metals, ceramics, and more. We can accommodate your material requirements.

Cost Efficiency: The efficiency of 3D printing enables us to reduce production and storage costs, which can significantly boost your profitability.

Customization and Optimization: We collaborate with you on the design and optimization of end parts to meet your specific needs and requirements.

Engineering and Optimization for Additive Manufacturing

Combining Skills and Technologies

We appreciate the opportunity to collaborate with you on engineering solutions and optimization for additive manufacturing (3D printing). Our company combines technical expertise with advanced 3D printing technologies to help you achieve optimal results in creating complex components and parts.

What can we offer you?

Engineering Expertise: Our engineers have extensive experience in additive manufacturing and understand the unique challenges that this technology brings. We are ready to work with you on the design and optimization of your parts.

Design for 3D Printing: Our design experts are capable of creating or modifying models to be ready for efficient 3D printing. This includes geometric optimization, weight reduction, and material optimization.

Material Consultation: We can assist you in selecting the right material for your needs. If your applications require special materials or parameters, we have ample experience with various types of printable materials.

Prototyping and Testing: Our services include prototyping and testing of your parts to ensure they meet your performance and quality requirements.

Cost Control: We strive to minimize costs in the production of parts without compromising on quality. This allows you to achieve maximum efficiency in the additive manufacturing process.

Background of strong companies

ABR 3D Print is part of ABR Invest, s.r.o., a company backed by traditional technology companies in the region with a turnover of over CZK 1 billion and more than 1,000 employees.

Cutting-edge technologies

We have high-end HP Multi Jet 5200 and Stratasys F900 printers, and a GOM ATOS Q 3D scanner.

Comprehensive services in the field of 3D printing

Everything from advice and design of the model, choice of material, to the printing and finishing.

Technologies

3D printing – MJF

HP Jet Fusion 5200

Fast production of plastic parts with repeatable precision. Best efficiency and cost-effectiveness of production compared to other additive technologies.

More about HP JF 52003D printing – FDM

Surface Finishing

Spray Painting

3D scanner

Products examples of applications

Available Materials

PMMA

There are 2 materials available for producing molds for precise casting with a high-quality surface finish. These materials differ in the mechanical strength achieved in the print.

Data Sheet

ABS-M30i

Strong, biocompatible material that can be sterilized and is suitable for use in medical devices. Meets ISO 10993, USP Class VI, and ISO 18562 testing requirements.

Data Sheet

ABS-M30™

Versatile material suitable for form, fit, and functional applications. Well-known manufacturing material for precision prototyping.

Data Sheet

ABS-ESD7™

Electrostatic dissipative material with surface resistance of 104 - 109 ohms. Great assembly tools for electronic and static-sensitive products. Widely used for functional prototypes of cases, covers, and enclosures.

Data Sheet

ASA

For the production of UV-stable parts with the best aesthetics among all FDM materials. Ideal for outdoor infrastructure and commercial use, outdoor functional prototypes, and automotive parts and accessories prototypes.

Data Sheet

PC-ABS

Excellent mechanical properties and thermal resistance. Excellent definition of features and surface aesthetics of ABS. Red PC-ABS is available as a Stratasys-approved material.

Data Sheet

PC-ISO

Sterilizable with gamma radiation or ethylene oxide (EtO) sterilization. Best suited for applications requiring higher strength and sterilization.

Data Sheet

PC (polycarbonate)

Precise, durable, and stable material for solid parts, metal bending tools, and working with composite materials. Excellent for demanding prototyping, tooling, and fixtures.

Data Sheet

FDM® Nylon 6

Combines strength and toughness better than other thermoplastics. Creates durable parts with a clean surface and high resistance to breakage.

Data Sheet

FDM® Nylon 12

The toughest nylon in additive manufacturing. Excellent for repeatedly used snap fits, pressed inserts, and fatigue-resistant applications.

Data Sheet

FDM® Nylon 12CF

Carbon fiber-reinforced thermoplastic with excellent structural properties. Highest flexural strength. Highest stiffness-to-weight ratio.

Data Sheet

ST-130™

Specially designed for hollow composite parts. Fast dissolution without manual processing. High resistance to heat and pressure in an autoclave.

Data Sheet

ULTEM™ 9085 resin

High thermal and chemical resistance; highest flexural strength. Meets FST (flame, smoke, toxicity) requirements.

Data Sheet

ULTEM™ 1010 resin

Highest thermal resistance, chemical resistance, and tensile strength. Excellent strength and thermal stability of ULTEM™ 9085 resin. High thermal and chemical resistance; highest flexural strength. Meets FST (flame, smoke, toxicity) requirements.

Data Sheet

PPSF

Mechanically excellent material, highest strength. Ideal for use in corrosive and highly thermally demanding conditions.

Data Sheet

Antero 840CN03

Excellent ESD (electrostatic) properties, strength, stiffness, and abrasion resistance. High thermal and chemical resistance. Low volatility and high dimensional stability.

Data Sheet

Antero™ 800NA

High thermal and chemical resistance. Low volatility and high dimensional stability. Excellent strength, stiffness, and wear resistance.

Data Sheet

HP PA12

HP PA12 is a material developed by HP. It is a durable thermoplastic for printing solid parts with high density and optimal technical properties.

Data Sheet

Main benefits

Dimensional inspection of printouts using a scanner

Comprehensive services from consultancy to printing and scanning

Elimination of the number of work steps in production

Design change without investing in moulds or jigs

Speed – immediate start of series production

ROI even with low numbers of units

Inquiry

News

Where to find usOur headquarters is located at ALTECH company area (Průmyslová 1146, 68601 Uherské Hradiště).

HP Multi Jet Fusion 5200The first piece of our technology that we want to introduce to you is the Multi Jet Fusion from Hewlett-Packard. The HP 5200 3D printer can efficiently produce larger series of nylon parts.

Contact us

and we will be more than happy to help you.

info@abr3dprint.com

+420 734 760 966

Where to find us

Our headquarters is located at ALTECH company area (Průmyslová 1146, 68601 Uherské Hradiště).